Altmark-Käserei Uelzena GmbH optimizes whey processing with raslysation technology

Altmark-Käserei Uelzena GmbH has taken an important step toward more sustainable dairy production by introducing raslysation, an innovative non-thermal processing technology developed by the Danish green tech company Lyras.

The collaboration enables gentle treatment of whey while maintaining high product quality, recovering more whey, extending production times, and reducing energy and water consumption. With this implementation, Altmark-Käserei strengthens its commitment to sustainable and future-oriented dairy processing.

A partnership driven by innovation and sustainability

Raslysation can replace traditional heat-based processes, which thereby protects valuable nutrients and improving process efficiency. The method also significantly reduces energy use and CO₂ emissions, key priorities in Altmark-Käserei’s ongoing sustainability strategy.

“At Altmark-Käserei, we are constantly working to improve both product quality and environmental performance. Raslysation helps us to extend production times, reduce cleaning and downtime, and thus significantly lower our energy and water consumption. With the introduction of this technology, we are taking another important step toward a more efficient and sustainable production process that meets the expectations of our customers and partners,” says Olaf Braumann, Managing Director of Altmark-Käserei Uelzena GmbH.

Mark Kalhøj Andersen, CEO of Lyras, adds:

“We are proud to collaborate with such an innovative partner as Altmark-Käserei Uelzena. Together, we have worked closely to make it possible to introduce a modern technology in a traditional industry in Germany, which plays a central role in the global food sector. Uelzena is setting a new benchmark for the dairy industry by implementing raslysation technology for the treatment of whey. This milestone demonstrates the company’s commitment to innovation, sustainability, and product quality, paving the way for others to follow.”

About Altmark-Käserei Uelzena GmbH

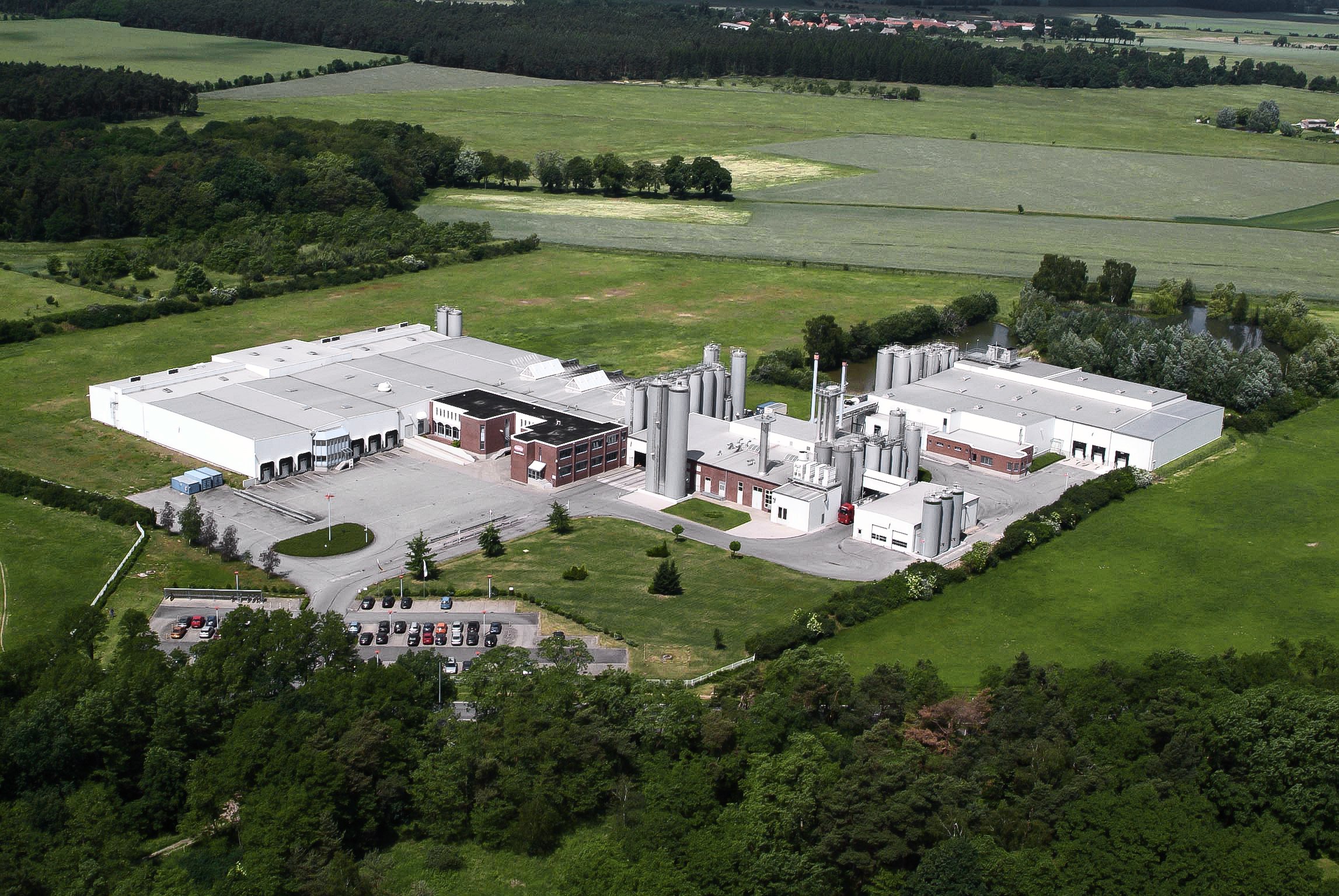

Altmark-Käserei Uelzena GmbH, based in Bismark (Saxony-Anhalt, Germany), is a subsidiary of the Uelzena Group. This production site has been producing Edam and Gouda semi-hard cheese since 1992, which produces high-quality whey. The company has decades of experience in whey processing and focuses on continuous improvement. It combines advanced industrial manufacturing expertise with modern, sustainable technology.

🔗Learn more at www.uelzena.de

About Raslysation™ by Lyras

Raslysation is a patented non-thermal liquid processing technology that can replace conventional pasteurization and microfiltration.

Raslysation inactivates microorganisms while preserving the natural proteins and vitamins of the product.

The process significantly reduces energy and water consumption, saving 60–90% of the energy and 60–80% of the water compared to traditional treatment methods, as well as reducing chemical use, delivering substantial CO₂ savings and improved product quality and food safety. Raslysation is used across many applications such as dairy, whey, brine, and process water, helping producers cut their carbon footprint and costs.

🔗Learn more about Raslysation https://tools.lyras.com/